What is Portland Cement?

Portland cement is the most commonly used type of cement in construction today. It serves as a critical ingredient in concrete, mortar, stucco, and grout, providing the necessary binding properties that contribute to the structural integrity of buildings and infrastructure. Its versatility and durability have made it a cornerstone of modern construction.

The Invention of Portland Cement

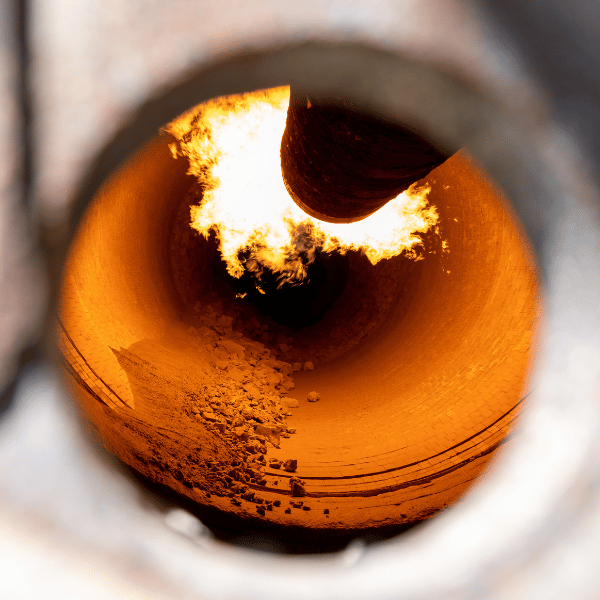

Portland cement was invented in 1824 by Joseph Aspdin, a British bricklayer. Aspdin created this new material by burning powdered limestone and clay in a furnace and grinding the resulting clinker into a fine powder. He named it "Portland" cement because the hardened cement resembled Portland stone, a popular building material in England at the time. This invention marked a significant advancement in construction materials, setting the foundation for the modern cement industry.

The Role of the Portland Cement Association (PCA)

The Portland Cement Association (PCA) was established in 1916 to represent and promote the cement industry in the United States. Over the years, PCA has played a pivotal role in research, innovation, and the development of standards that have shaped the industry. Notably, the PCA has been instrumental in advancing the use of cement in various applications, from residential construction to large-scale infrastructure projects like highways and bridges.

Key Milestones in the History of Portland Cement

19th Century Developments

Following Aspdin's invention, the manufacture of Portland cement spread across Europe and into the United States. By the late 19th century, technological advancements such as the introduction of the rotary kiln allowed for more efficient and consistent production of Portland cement.

20th Century Expansion

The early 20th century saw the widespread adoption of Portland cement in the United States, largely displacing imported cement. The PCA's efforts during this period were crucial in establishing cement as a dominant material in construction, particularly through its research initiatives and the development of industry standards.

Modern Day Innovations

Today, the focus of Portland cement production includes sustainability and reducing the environmental impact of cement manufacturing. The PCA continues to lead in these areas, promoting research into carbon capture, alternative materials, and other innovations aimed at making cement production more eco-friendly.

The Impact of Portland Cement on Construction

The invention and subsequent development of Portland cement revolutionized construction. Its ability to create strong, durable structures has been fundamental to the growth of cities and infrastructure around the world. From towering skyscrapers to expansive highways, Portland cement is a key component in nearly every major construction project.

How Portland Cement is Used in Soil Stabilization

Portland cement plays a crucial role in soil stabilization, a process that enhances the physical properties of soil to improve its load-bearing capacity and make it suitable for construction. This is particularly important in areas where the native soil is too weak or unstable to support buildings, roads, or other infrastructure. Here’s how Portland cement is used in this process:

1. Mechanism of Soil Stabilization with Portland Cement

Soil stabilization using Portland cement involves mixing the cement with the soil, followed by the addition of water to initiate a chemical reaction known as hydration. During hydration, the cement particles react with water to form calcium silicate hydrate (C-S-H) and calcium hydroxide. These compounds bind the soil particles together, significantly increasing the soil's strength and reducing its plasticity.

This chemical reaction also results in the formation of a rigid matrix within the soil, which reduces its ability to absorb water and swell. As a result, the stabilized soil exhibits improved load-bearing capacity, reduced shrink-swell potential, and greater resistance to erosion

2. Applications of Portland Cement in Soil Stabilization

Portland cement is widely used in various soil stabilization applications, including:

- Road Construction: Stabilized soils provide a strong base layer for roads, reducing the need for additional materials and ensuring long-term durability.

- Foundation Support: In construction projects where the native soil is not strong enough to support the weight of a structure, Portland cement stabilization is used to improve the soil's load-bearing capacity.

- Erosion Control: Stabilized soil is more resistant to erosion, making it ideal for use in embankments, slopes, and other areas prone to water runoff.

3. Process of Soil Stabilization with Portland Cement

The process typically involves the following steps:

- Soil Assessment: The first step is to evaluate the soil's properties, such as its moisture content, particle size, and plasticity. This assessment helps determine the appropriate amount of cement to be added.

- Mixing: Portland cement is mixed with the soil at a rate that is usually between 2% to 5% by weight. The mixing process ensures that the cement is evenly distributed throughout the soil.

- Hydration and Compaction: After the cement is thoroughly mixed with the soil, water is added to initiate the hydration process. The soil is then compacted to the desired density, which enhances its strength and stability.

- Curing: The stabilized soil is allowed to cure over a period of several days, during which time it continues to gain strength.

4. Benefits of Using Portland Cement for Soil Stabilization

- Increased Strength: The chemical reaction between Portland cement and the soil results in a material that is much stronger than the original soil, capable of supporting heavy loads.

- Improved Durability: Stabilized soils are more resistant to environmental factors such as moisture, temperature changes, and erosion.

- Cost-Effective: Compared to other stabilization methods, using Portland cement is often more economical, especially for large-scale projects.

How is Portland Cement Different from Regular Cement?

Portland cement is a specific type of cement, and it differs from what is often referred to as "regular" or general-purpose cement in several key ways. While all Portland cement can be considered a type of regular cement, not all regular cements are Portland cement. Here are the main differences:

1. Composition

Portland cement is composed primarily of clinker, a material made by heating limestone and clay at high temperatures in a kiln. This clinker is then ground into a fine powder and mixed with gypsum to control the setting time. The specific combination of calcium silicates and other compounds in Portland cement gives it its unique hydraulic properties—meaning it can set and harden underwater.

In contrast, other types of regular cement may include different mixtures of materials and additives depending on their intended use. For example, masonry cement is a blend of Portland cement with other materials such as limestone and plasticizers, designed for use in mortar.

2. Strength and Durability

Portland cement is known for its high strength and durability, making it the cement of choice for most construction applications, including buildings, bridges, and roads. It provides excellent long-term stability and resistance to environmental factors such as moisture and temperature changes.

Other types of cement may be formulated for specific purposes, such as rapid-setting cements, which are designed to harden quickly but may not provide the same long-term durability as Portland cement.

3. Hydraulic Properties

One of the defining characteristics of Portland cement is its hydraulic nature, meaning it hardens when mixed with water and retains its strength even in wet conditions. This makes it ideal for use in concrete, which is often exposed to water and other elements.

Non-hydraulic cements, on the other hand, such as lime-based cements, rely on a chemical reaction with carbon dioxide in the air to harden. These cements do not perform well in wet conditions and are typically used in more specialized applications.

4. Applications

Portland cement is the most commonly used type of cement in the world, accounting for about 95% of all cement production. Its primary use is in the production of concrete, which is a mixture of cement, sand, aggregate, and water. Portland cement is also used in mortar, grout, and plaster.

Regular cements may include other varieties, such as sulfate-resistant cement, which is designed for environments with high sulfate exposure, or white cement, which is used for decorative purposes due to its bright color.

Portland Cement - A Universal Solution

Portland cement remains a vital material in construction, nearly two centuries after its invention. Thanks to the ongoing efforts of organizations like the Portland Cement Association, the cement industry continues to evolve, meeting the demands of modern construction while addressing environmental concerns. Understanding the history and importance of Portland cement helps us appreciate its role in shaping the world we live in today. If you are researching portland cement for a job site drying project, call the soil stabilization experts at Ruston Paving. You can reach us at or by filling out the form below.