Full Depth Reclamation Stabilization Asphalt Milling Brochures & Links

At Ruston Paving, our comprehensive full-depth reclamation (FDR) services are tailored to meet the diverse needs of every project. From revitalizing deteriorated pavements to minimizing environmental impact, our full-depth reclamation process delivers long-lasting results that exceed expectations.

A Definition of Full-Depth Reclamation

“Full-depth reclamation is a reclamation technique in which the full flexible pavement section and a predetermined portion of the underlying materials are uniformly crushed, pulverized, or blended, resulting in a stabilized base course. Further stabilization may be obtained through the use of available additives.”

– Asphalt Recycling & Reclaiming Association

The Full-Depth Reclamation Process

At Ruston Paving, we utilize state-of-the-art equipment and proven techniques to rejuvenate worn-out pavements, extending their lifespan and enhancing their performance.

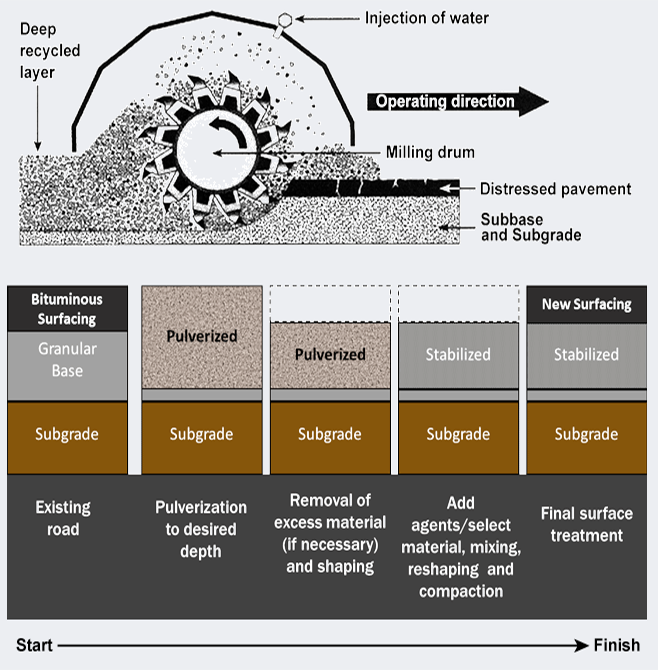

Pulverization

First, the existing asphalt pavement and a portion of the underlying materials are pulverized using specialized equipment, such as reclaimers or pulverizers, to break them down into smaller particles.

The FDR Construction Process

Blending

The pulverized materials are thoroughly mixed together to ensure uniform distribution of aggregates, binders, and a stabilizing agent.

Compaction

The blended mixture is compacted using heavy rollers or compactors to achieve the desired density and strength, creating a stable base for the new asphalt pavement.

The Benefits of Full-Depth Reclamation

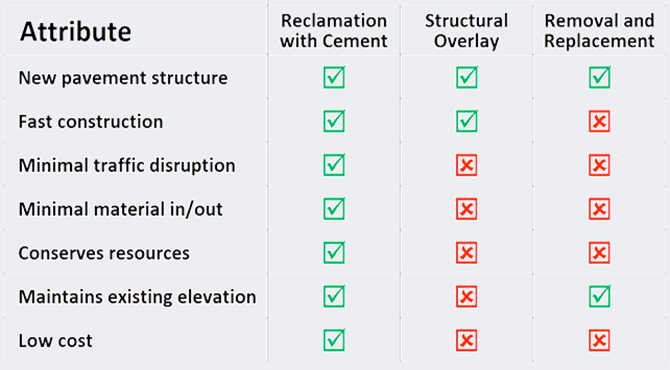

Full-depth reclamation is one of the most cost-effective, eco-conscious, and efficient methods of asphalt pavement recycling.

Improved Performance

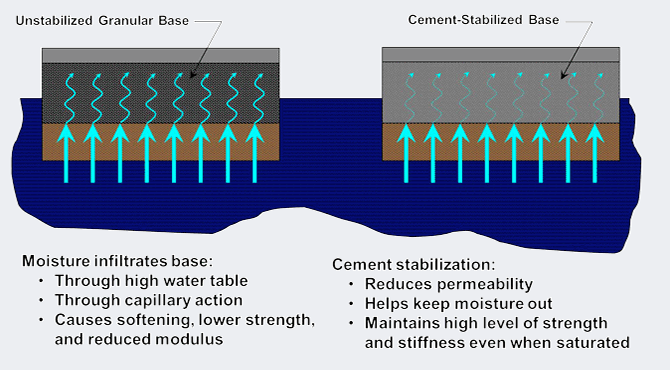

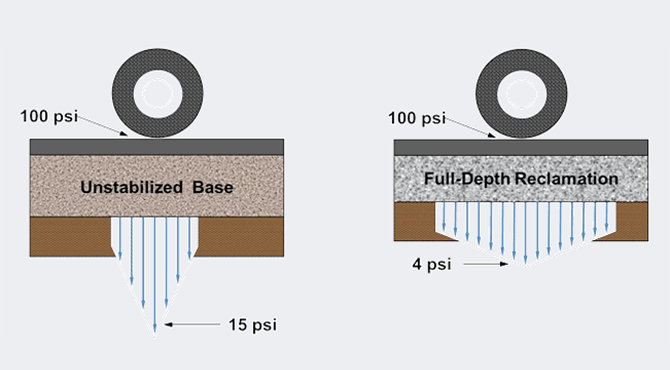

Full-depth reclamation produces a stabilized base that is inherently stronger and more durable than the old asphalt pavement. This fortified foundation enables pavements to withstand heavy traffic loads, resist deformation, and stand up to environmental stresses such as freeze-thaw cycles and moisture infiltration. Full-depth reclamation process eliminates concerns of reflective cracking, and improves resistance to frost penetration in sub-grade.

Conserves Energy

By recycling existing pavement materials, full-depth reclamation eliminates the need to transport materials to and from the construction site, reducing fuel consumption and associated emissions. The process involves fewer machinery operations compared to traditional methods, further lowering energy consumption during construction.

Conserves Material

Through the pulverization, blending, and compaction process, FDR repurposes the existing pavement and a portion of the underlying materials to create a strong and durable base for a new pavement surface. By reusing materials already present on-site, full-depth reclamation significantly reduces the demand for new aggregates, asphalt binder, and other construction materials, further enhancing its material conservation benefits.

Cost Effective

By recycling existing pavement materials, full-depth reclamation significantly reduces the need for importing new materials, which can be costly. Plus the streamlined process of pulverization, blending, and compaction minimizes construction time, leading to additional savings in labor and equipment costs.

Future maintenance costs are also reduced by improving product performance.

Environmentally Friendly

Full-depth reclamation effectively minimizes waste generation and reduces the burden on landfills, making it more environmentally-friendly option. The conservation of natural resources is a key aspect of FDR, as it eliminates the need for excessive extraction of raw materials and encourages recycling. Pollution resulting from heating mixing and hauling are also reduced.

Full-Depth Reclamation Applications

Private Roads and Subdivisions

FDR is a great choice for rehabilitating heavily trafficked roads and highways, where durability and longevity are non-negotiable. This process offers a comprehensive approach to address the wear and tear faced by a roadway, by creating a stabilized base that can withstand the rigors of heavy traffic loads and adverse weather conditions.

Parking Lots

Parking lots are subjected to constant use from vehicles, foot traffic, and environmental factors, leading to deterioration over time. FDR can revitalize deteriorating parking lots, offering both cost-effectiveness and sustainability. By using existing material and creating a stabilized base, FDR transforms worn-out parking lots into durable and resilient surfaces capable of enduring the demands of daily use.

Industrial Facilities

Industrial facilities with heavy machinery traffic pose unique challenges for pavement durability and resilience. The constant movement of heavy equipment and machinery can exert significant stress on pavements. FDR is well-suited for these challenges, offering industrial facilities a durable and resilient pavement surface capable of withstanding heavy loads and harsh operating conditions.

Our Other Services

Ruston Paving offers several services that can be made more effective with the addition of soil stabilization.

Asphalt Milling

Asphalt milling, also referred to as cold milling or profiling, involves the precise removal of the upper layer of an existing asphalt pavement using specialized machinery. This process yields a milled surface that can be repurposed through recycling or utilized as a sturdy base for subsequent pavement layers. By efficiently extracting old pavement layers, asphalt milling serves as a vital step in pavement rehabilitation, preparing the surface for further treatment or reconstruction.

Soil Stabilization

Soil stabilization complements full-depth reclamation by enhancing the strength and durability of the reclaimed base, further improving its performance and longevity. Through the addition of a stabilizing agent, such as Portland cement, soil stabilization fortifies the reclaimed base, increasing its load-bearing capacity and resistance to environmental stresses.

Contact Us for Your Reclaimed Pavement Projects Today!

With a full suite of asphalt recycling techniques and equipment, Ruston Paving offers sustainable cost-effective solutions for your projects. Contact Ruston Paving to learn more about our full-depth reclamation services and make surface integrity the foundation of all your projects.