Full Depth Reclamation Stabilization Asphalt Milling Brochures & Links

Recycled Asphalt Service

The right recycled asphalt service for you will depend on your unique needs. Each project may necessitate different levels of each service depending on factors such as pavement condition, traffic volume, environmental considerations, and budget constraints.

Asphalt milling serves as the initial step in the recycling process, where the top layer of deteriorated pavement is removed, leaving behind a smooth and even surface. This process is particularly beneficial for surface-level distresses and is commonly utilized as a preparatory step for further recycling techniques.

With state-of-the-art equipment and a team of skilled professionals, Ruston Paving delivers effective asphalt milling services tailored to meet the unique needs of each pavement project. Whether it's a small-scale rehabilitation or a large-scale parking lot reconstruction, we deliver superior results every time.

Learn more about our asphalt milling services to discover how Ruston Paving can help you achieve durable, high-quality asphalt pavement while minimizing environmental impact and maximizing cost savings. Trust us to pave the way for a smoother, more sustainable future.

A Definition of Asphalt Milling:

Asphalt milling is the controlled removal and recycling of an existing surface to correct and restore the surface to a specified profile. The process generates recycled asphalt pavement (RAP) for use in place of virgin aggregate in new asphalt material.

Benefits of Asphalt Milling Services

Asphalt milling not only rejuvenates any aging asphalt surface, it also provides a valuable opportunity for recycling and reusing asphalt materials, reducing waste and conserving natural resources. The benefits of asphalt milling include:

A Sustainable Process

Recycling existing materials and using the RAP instead of virgin aggregate in the new asphalt pavement saves natural resources and energy. The process can be repeated over and over again on the same surface.

Environmentally Friendly

The RAP can be used in place of a portion of the virgin aggregate and asphalt binder, which can lower the energy and greenhouse gas (GHG) footprint of the material production process. RAP is re-used and, therefore kept out of landfills.

Improved Project Schedule

Under most circumstances, traffic flow is maintained and able to immediately travel on the milled surface.

An Improved Surface

Existing curb and gutter reveals are maintained through asphalt milling, and surface drainage is improved. Plus, bumps, ruts and other surface irregularities are eliminated through these services.

Cost Effective

Asphalt milling services are done at a lower cost than reconstruction, maintenance budgets can cover a larger footprint.

The Asphalt Milling Process

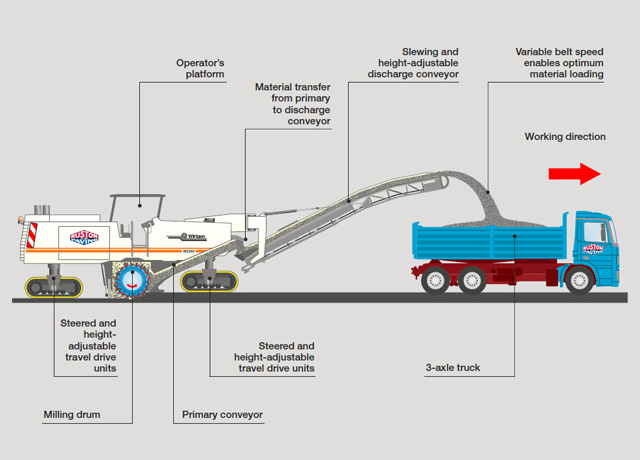

The asphalt milling process, also known as cold planing, is a reclaimed asphalt pavement process used to remove the top layer of an existing asphalt surface to prepare it for resurfacing or reconstruction.

The pavement milling machine grinds away the deteriorated surface of the old asphalt pavement, leaving behind a smooth and even base. This method not only improves the overall pavement quality but also allows for the recycling and reuse of the milled materials, reducing waste and conserving resources. The milled asphalt is collected and transported to recycling facilities, where it can be processed and used in new pavement mixtures. The asphalt milling process is a cost-effective and sustainable solution for rejuvenating asphalt surfaces while minimizing environmental impact.

Our Other Services

Ruston Paving offers several services that can be made more effective with the addition of soil stabilization.

Full-Depth Reclamation

Full-depth reclamation is a comprehensive approach to pavement rehabilitation. It involves the pulverization of the old pavement alongside a portion of the underlying materials, followed by thorough blending and compaction of the mixture. This method yields a robust and durable base, primed for the installation of a new pavement surface.

Soil Stabilization

Soil stabilization complements full-depth reclamation by enhancing the strength and durability of the reclaimed base, further improving its performance and longevity. Through the addition of a stabilizing agent, such as Portland cement, soil stabilization fortifies the reclaimed base, increasing its load-bearing capacity and resistance to environmental stresses.