Full Depth Reclamation Stabilization Asphalt Milling Brochures & Links

Time-Tested Soil Stabilization and Soil Preparation

Make sure the ground beneath your organization can handle the shifting loads of daily life by using our proven soil stabilization process.

Step 1: Testing

When requested, lab tests analyze the aggregate and soil selected for the project and a custom combination of depth, additive and water is designed to meet the load-bearing capacity required for the use of the site.

Step 2: Spread Mixing

In most cases, the soil and aggregates are pre-existing on site and the proper quantity of additive is applied onto the surface with a calibrated spreader. Then, in one step, a reclaimer/stabilizer blends the soil/aggregates, additive and the optimum amount of water to the required depth.

Step 3: Compaction/Curing

The blended mixture is then compacted using vibratory rollers. Once hardened, the modified material does not compact further under traffic and is resistant to settling. This results in a ready-to-use, durable, subgrade or base.

Step 4: Construction

The entire soil stabilization process can be completed over large areas in one day. From there, further construction operations can then continue on top of the improved surface.

A Definition of Soil Stabilization

"Stabilization is the permanent physical and chemical alteration of soils and aggregates to enhance their engineering properties thus improving the load-bearing capacity of a sub-grade or sub-base to support pavements and foundations."

-Asphalt Recycling & Reclaiming Association, Soil Stabilization Experts

Stabilize Soil with Ruston Paving

Soil stabilization is often employed in construction and civil engineering to fortify the ground; ensuring that roads, buildings, and other structures remain durable and safe over time.

Whether used in conjunction with other methods or by itself, soil stabilization is a cost-effective and environmentally friendly process with a major payoff.

The Benefits of Soil Stabilization Service

When you opt to stabilize weak soil before starting your project, you’re making a sound investment in its strength and longevity.

Pro-Active Solution

The soil stabilization process addresses underperforming sub-grades before construction rather than reacting to the problem afterward with costly repairs to pavements, building slabs, and foundations.

Plus it offers improved resistance to frost penetration in sub-grade.

Improved Project Schedule

Soil stabilization service allows for immediate access to sites that otherwise might not be accessible due to poor sub-grade conditions.

Conserves Energy

The in-place nature of the process means no hauling away or importing of new engineered material.

Conserves Material

Increased load bearing capacity means reduced need for over designed footings, slabs and pavement sections.

Cost Effective

Investing in soil stabilization upfront can lead to substantial cost savings in the long run by reducing the need for frequent maintenance and repairs that weak soils may necessitate.

Environmentally Friendly Alternative

Pollution resulting from material hauling is practically eliminated, addressing the ever-growing environmental concerns of many clients.

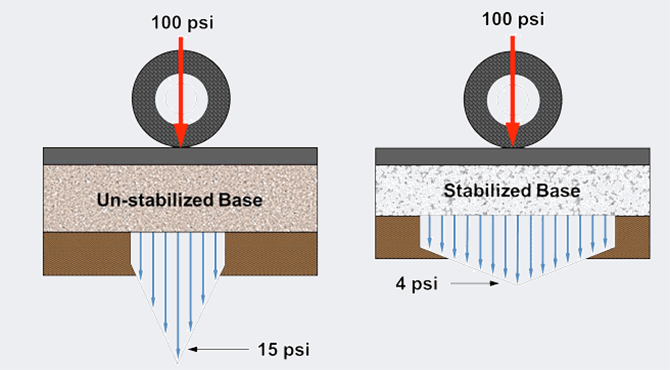

Increased Load Bearing Capacity

By stabilizing the soil, engineers can significantly increase the strength and load-bearing capacity of structural foundations built on it, allowing it to support heavy structures and vehicular traffic more effectively.

Why Do Soil Stabilization?

Soil Stabilization Applications

Stabilizing the soil underneath the pavement will greatly increase the load capacity and longevity of the asphalt. By taking the time to properly prepare the soil, you can save time and thousands of dollars on repairs down the road.

Private Road Construction

Stabilized soil is used as a base or sub-base material in road construction to provide a solid foundation for asphalt or concrete pavements.

Building Foundations

Stabilized soil is essential for constructing stable building foundations that can withstand the weight of the structure and prevent settlement.

Parking Lots

A stable soil foundation is the key to a durable and reliable parking lot. By treating the soil with special materials, we make sure it can handle the weight of cars and trucks without sinking or cracking. This means fewer potholes and less need for repairs, keeping the parking lot smooth and safe for everyone. Plus, it helps prevent problems like erosion and water damage, making the parking lot last longer and stay in good shape.

Soil Stabilization Methods

There are a few soil stabilization methods that may be applied, depending on the types of soil, nature of the project, and a few other factors.

Our Other Services

Ruston Paving offers several services that can be made more effective with the addition of soil stabilization.

Asphalt Milling

Asphalt milling, also referred to as cold milling or profiling, involves the precise removal of the upper layer of an existing asphalt pavement using specialized machinery. This process yields a milled surface that can be repurposed through recycling or utilized as a sturdy base for subsequent pavement layers. By efficiently extracting old pavement layers, asphalt milling serves as a vital step in pavement rehabilitation, preparing the surface for further treatment or reconstruction.

Full-Depth Reclamation

Full-depth reclamation is a comprehensive approach to pavement rehabilitation. It involves the pulverization of the old pavement alongside a portion of the underlying materials, followed by thorough blending and compaction of the mixture. This method yields a robust and durable base, primed for the installation of a new pavement surface.

Contact Us for Soil Stabilization Today!

Ruston Paving has the soil stabilization methods to suit each and every project. Get in touch with us today to learn more!