Full Depth Reclamation Stabilization Asphalt Milling Brochures & Links

The milling process is the only way to remove or modify an existing asphalt surface with a specified, consistent removal depth. Pavement milling removes the top layers of a paved surface area that is either in bad condition or needs to be resurfaced. This process is recommended when only the top two inches of asphalt needs to be replaced, instead of a full-depth restoration.

Our milling service can restore the integrity of your pavement if it shows signs of wear but remains structurally sound. We remove the top layer of asphalt, profile the surface for proper drainage, and apply a tack coat before laying down a new asphalt layer, effectively revitalizing your surface.

What is Asphalt Milling?

Asphalt milling (also known as cold planing or rotomilling) is the process of removing the top layer(s) of an existing asphalt pavement using specialized milling machines. This process is used to prepare surfaces for new overlays, repairs, or to correct surface irregularities. The removed asphalt, called millings or Reclaimed Asphalt Pavement (RAP), can be recycled and used in new asphalt mixes.

How is Asphalt Milling Done?

This is how asphalt milling works:

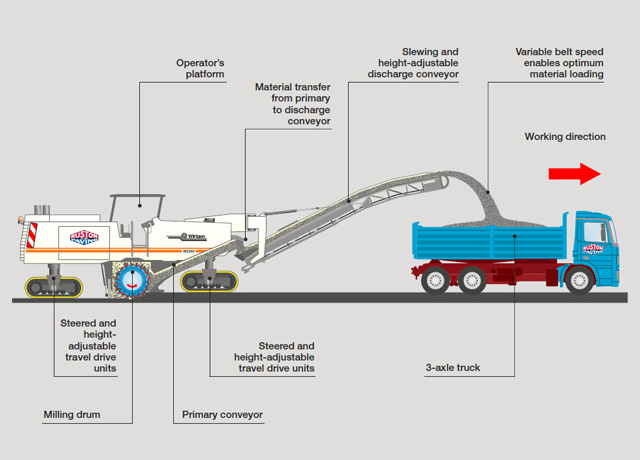

- Milling Machines: Asphalt milling is performed using machines equipped with rotating drums fitted with carbide-tipped cutting teeth. These teeth grind away the asphalt surface to the desired depth.

- Depth of Milling: The depth of milling can vary depending on the project, ranging from shallow surface removal to deeper cuts that reach the base layer.

- Material Recycling: The ground-up asphalt is conveyed into dump trucks and transported for recycling. This recycled material, known as RAP, is a key component in new asphalt mixes.

- Surface Preparation: Milling removes damaged or deteriorated asphalt, creating a clean, level surface for new pavement or repairs. It also helps improve drainage and can enhance the bonding of new asphalt layers.

Why Mill?

Signs You Need Asphalt Milling

When you see these signs, you need to mill your asphalt:

- Your pavement has started to disintegrate from the top down.

- Surface cracking has allowed water to penetrate the pavement and cause deterioration.

- The top layer of asphalt is

- The asphalt pavement is in a critical drainage area that is impaired, and the water is not draining properly.

- Pavement shows signs of low and moderate cracking.

Reasons to Mill on Your Next Asphalt Repair Project

Benefits of Asphalt Milling

Creates an Improved Surface

- Restores pavement to a uniform cross-section by eliminating bumps, ruts, and other surface irregularities.

- Restores drainage flow and provides a textured surface for skid control.

- Restores curb-reveal for roadways and parking areas that have had numerous overlays.

Is a Time-Efficient Process

- Requires minimal traffic interruption to the traffic flow

- Some of the larger milling machines, depending on the depth of the cut, can cut close to 15,000 square yards a day, at 75 feet per minute. This makes milling very cost-effective for large surfaces such as streets, highways, runways, and large parking lots.

Is Environmentally Friendly

- The process generates no smoke or flame, and the small amount of dust is easily controlled.

- Reclaimed material can be retained for future use, providing for a more sustainable environment.

Our Other Services

Ruston Paving offers several services that can be made more effective with the addition of soil stabilization.

Full-Depth Reclamation

Full-depth reclamation is a comprehensive approach to pavement rehabilitation. It involves the pulverization of the old pavement alongside a portion of the underlying materials, followed by thorough blending and compaction of the mixture. This method yields a robust and durable base, primed for the installation of a new pavement surface.

Soil Stabilization

Soil stabilization complements full-depth reclamation by enhancing the strength and durability of the reclaimed base, further improving its performance and longevity. Through the addition of a stabilizing agent, such as Portland cement, soil stabilization fortifies the reclaimed base, increasing its load-bearing capacity and resistance to environmental stresses.