When it comes to creating smooth and durable road surfaces, parking lots, and driveways, asphalt is a top choice for its reliability and cost-effectiveness. But have you ever wondered how existing asphalt surfaces are rejuvenated and prepared for a fresh layer of asphalt? The answer lies in a crucial process known as asphalt milling. In this comprehensive guide, the experts at Ruston Paving take an in-depth look into the world of asphalt recycling to uncover its importance, techniques, and the transformative impact it has on pavement infrastructure.

Whether you're a property manager, a business owner, or simply someone curious about the intricacies of asphalt paving, we are here to help you discover how asphalt milling contributes to the longevity and functionality of paved surfaces.

What is the Purpose of Asphalt Milling?

The purpose of asphalt milling, also known as cold milling or profiling, is multifaceted and plays a crucial role in the maintenance and construction of asphalt surfaces. Let’s take a closer look at the primary purposes of asphalt milling.

Surface Preparation

Asphalt milling is often the first step in preparing an existing asphalt surface for renovation or resurfacing. It removes the top layer of worn-out or damaged asphalt, which may include cracks, potholes, and surface irregularities. By eliminating these surface defects, asphalt milling provides a clean and even base for the application of a new asphalt layer.

Pavement Recycling

Asphalt milling allows for the recycling of existing asphalt materials, reducing the need for new raw materials and minimizing waste. The milled asphalt can be collected, processed, and reused in future paving projects, making it an environmentally sustainable practice.

Improved Surface Smoothness

Over time, asphalt surfaces can become uneven and rough due to factors such as weathering, traffic, and wear and tear. Asphalt milling removes these imperfections, resulting in a smoother and more aesthetically pleasing surface that enhances driving comfort and safety.

Adjusting Surface Profiles

Milling can be used to adjust the profile or slope of an asphalt surface to improve drainage. This is particularly important for roadways and parking lots to prevent water from pooling and causing damage over time. Proper drainage helps extend the life of the pavement and reduces the risk of water-related issues.

Restoration of Skid Resistance

Over time, asphalt surfaces may lose their skid resistance due to wear and surface oxidation. Milling removes the top layer, exposing a fresh and textured surface that will allow the new asphalt course to properly bond with the underlying layer that enhances traction and helps to prevent accidents, especially during wet or icy conditions.

Cost-Effective Repairs

Instead of completely removing and replacing an entire asphalt surface, which can be expensive and disruptive, asphalt milling allows for targeted repairs. It selectively removes damaged areas while leaving structurally sound pavement intact, saving time and money.

Surface Prepping for Overlays

When a new layer of asphalt is applied to an existing surface, milling provides the ideal substrate for the overlay to adhere to. This ensures a strong bond between the old and new layers, enhancing the longevity and performance of the pavement.

What Does an Asphalt Milling Machine Do?

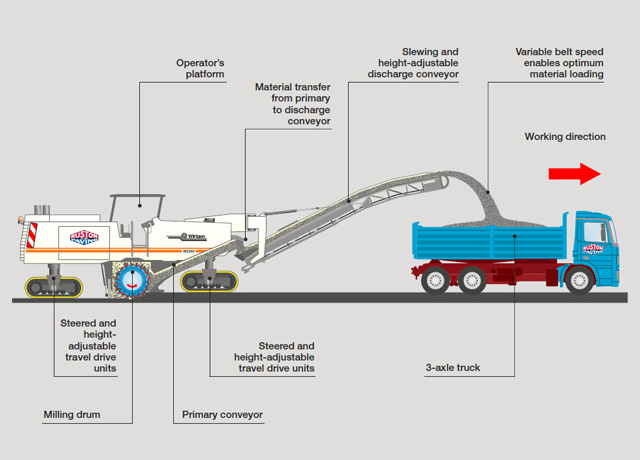

An asphalt milling machine, also known as a cold planer or pavement milling machine, is a specialized piece of heavy equipment used in the asphalt milling process. Its primary function is to remove the top layer of an existing asphalt surface to prepare it for resurfacing or rehabilitation.

Surface Removal

The primary task of an asphalt milling machine is to remove the top layer of asphalt from a pavement surface. This involves rotating cutting drums equipped with sharp teeth or milling bits that grind and cut into the asphalt. The machine's adjustable depth control allows operators to select the desired depth of milling, which can range from a fraction of an inch to several inches, depending on the project requirements.

Material Collection

As the milling machine grinds the surface asphalt layer, it simultaneously collects the milled material, which is typically a mix of crushed aggregate and asphalt. This material is conveyed into a holding chamber or conveyor system within the machine.

Surface Profiling

Asphalt milling machines are capable of creating a smooth and even profile on the milled surface. By removing imperfections, such as potholes, cracks, and irregularities, they ensure that the new asphalt layer adheres securely to the milled base. Profiling also helps with water drainage and surface texture improvements.

Recycling

The collected milled material can be recycled and reused in future asphalt projects, reducing the need for fresh asphalt and minimizing waste. Recycling milled asphalt is an environmentally sustainable practice that conserves resources and reduces the carbon footprint associated with asphalt production.

Precision Control

Modern asphalt milling machines are equipped with advanced technologies and computerized controls that allow operators to maintain precise cutting depths, control the machine's speed, and ensure consistent milling results. This precision is crucial for achieving the desired surface quality.

Versatility

Asphalt milling machines come in various sizes and configurations, making them suitable for a wide range of projects. They can tackle everything from small driveway repairs to large-scale highway milling, adapting to different asphalt thicknesses and surface conditions.

Safety Features

Safety is a paramount concern when operating heavy machinery. Asphalt milling machines are designed with safety features such as operator stations with excellent visibility, backup cameras, and emergency shut-off systems to protect both operators and workers in the vicinity. Equally important to safety features on equipment, providing safety training for all members of the team can save lives.

What Are the Different Types of Asphalt Machines for Milling?

There are several different types of asphalt milling machines, each designed for specific purposes and project requirements. These machines vary in size, capabilities, and features.

Cold Planers

Standard cold planers are the most common type of milling machines. They come in various sizes and configurations, suitable for a wide range of projects, from minor road repairs to larger highway milling jobs. These machines offer versatility and efficiency.

Small Cold Planers

Also known as mini or compact cold planers, these machines are relatively small and are often used for precision work on smaller projects, such as driveway repairs or patching. They are highly maneuverable and can access tight spaces.

Large Cold Planers

Large cold planers are heavy-duty machines designed for high-production milling tasks, such as major highway rehabilitation or airport runway resurfacing. They have a wide working width and can remove thick asphalt layers in a single pass.

Track Cold Planers

Track cold planers are equipped with tracks instead of wheels, which provide better stability and weight distribution. They are ideal for working on uneven terrain or when precise control is needed.

Drum-style Milling Machines

These machines have rotating drums equipped with cutting teeth or milling bits that grind and remove the asphalt. Drum-style machines are the most common and are available in various sizes and configurations.

Wheel-type Milling Machines

These machines have wheels instead of tracks and are suitable for projects where mobility and speed are essential. They are often used for road resurfacing and repair work.

Integrated Mill-and-Fill Machines

Some milling machines are designed to perform both milling and paving in one continuous operation. These integrated machines streamline the process by milling the old surface and immediately placing a new layer of asphalt.

Road Profilers

Road profilers are specialized milling machines used to create precise road profiles for road construction projects. They ensure that the road surface meets specific elevation and smoothness requirements.

Half-lane and Full-lane Milling Machines

These large milling machines are capable of removing significant sections of asphalt in a single pass. They are commonly used for highway construction and major road rehabilitation.

What is the Asphalt Milling Process?

The asphalt milling process, also known as cold milling or profiling, is a systematic and highly controlled operation that involves the removal of the top layer of an existing asphalt pavement.

Here is an overview of the asphalt milling process:

- Preparation: Marking the milling boundaries, setting up traffic control measures (if necessary), and inspecting the milling machine to ensure it's in proper working condition.

- Positioning the Milling Machine: Operators carefully align the machine to ensure precise milling.

- Adjusting Milling Depth: The operator sets the desired milling depth based on project requirements.

- Milling Operation: The milling machine is activated, and its cutting drums, equipped with sharp teeth or milling bits, begin to rotate. These cutting elements grind and cut into the asphalt, removing the top layer systematically.

- Material Collection: As the milling machine grinds away the asphalt, it collects the milled material, including crushed asphalt, aggregate, and bitumen.

- Surface Profiling: Depending on the project requirements, the milling machine may be used to create a specific surface profile, which can improve water drainage and ensure proper adhesion of the new asphalt layer.

- Cleanup: Once milling is complete, the milled material is either loaded onto trucks for recycling or disposed of in an environmentally responsible manner.

- Overlay or Surface Treatment: In many cases, the milling process is followed by the application of a new asphalt overlay or surface treatment. The milled surface provides an ideal substrate for the new asphalt layer, ensuring a strong bond.

Contact Our Experts in Asphalt Paving Today

If you're considering an asphalt paving project or have any questions about the process, don't hesitate to reach out to our top-rated team of paving experts. Our experienced professionals at Ruston Paving are ready to assist you every step of the way, from planning and material selection to the final installation of your asphalt surface. Call us at (800) 727-6223 to speak to an asphalt paving professional today. You can also reach out to us via the online contact form.