Join Our Team Today

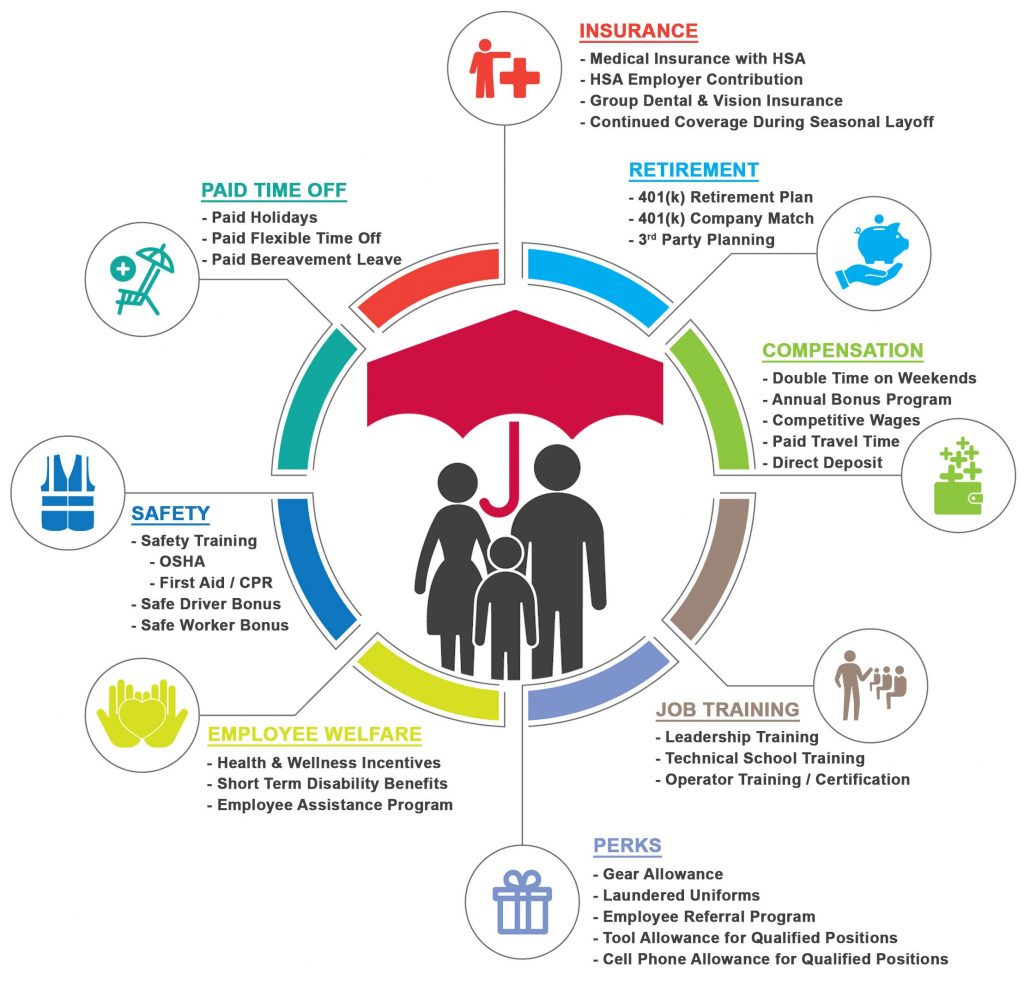

At Ruston Paving, we understand that our greatest asset is our workforce, which is why we're constantly striving to improve the effectiveness of our employees. In order for our company to perform at its best, our people must be at their best. We provide our people with strong benefits and many innovative health and wellness inspired programs that help fuel their winning contributions.

Check out what we're doing by visiting our SOCIAL media platforms.

Scroll down to view our current openings

Here are our employee benefits and division locations at a glance.

Employment Opportunities

Ruston Paving Company, Inc. has many employment opportunities available. If you are interested in pursuing one of these opportunities, please select the location and position you are interested in to complete an application. Once you have applied for one position at any location, you can easily apply to the other positions without duplicated effort.

You may also visit the nearest Ruston Paving Co., Inc. location to complete the online application at our office with assistance. A representative will contact you if there is an immediate need for employees with your qualifications and experience.

Employment is subject to review of background check and drug screening. Ruston Paving Co. Inc. is an equal opportunity employer.